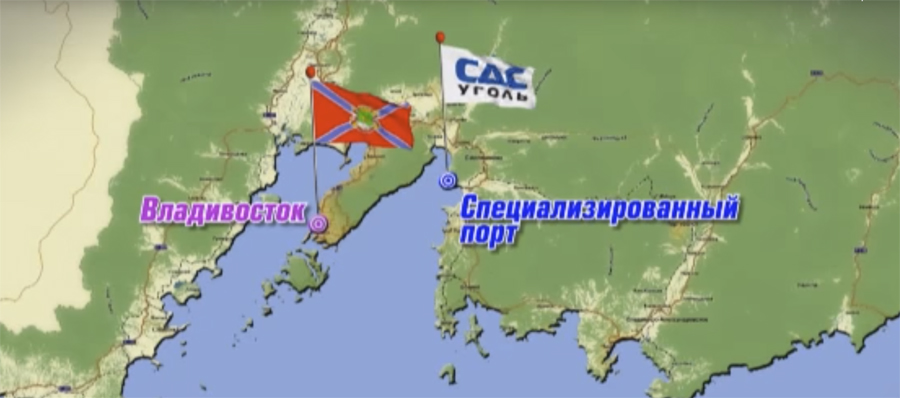

The construction of berths 1 and 2 at the Sukhodol sea port in Primorsky krai is underway. Morstroytechnology is chief designer on the project (see here for further details), and the port in the bay of Sukhodol is one of the priority investment projects for the Primorsk region.

The construction work is being carried out by AO Trest Gydromontazh, whose general director announced that the main construction equipment and machinery had commenced operations on the site of the Sukhodol sea port.

Six cranes with a lifting capacity of between 100 and 300 tonnes have been delivered to the site, along with two 100 tonne floating cranes, technical support vessels, heavy duty piledriving equipment, and all the necessary construction materials (steel piles, cleats, anchoring systems and inert materials). In addition, local production of concrete castings has begun, and accommodation for the engineers and construction workers has been organised.

At the present moment, Trest Gydromontazh's own full-time employees are working on site (around 200 people), and in the future it is planned to increase the site workforce to 1,000 in order to carry out the main construction phase and complete all works in 2020.

Sukhodol will service vessels with a maximum deadweight of 120,000t. The port will have two berths over 600m in length, along with other facilities including a 170ha storage area which will be able to hold up to 1.2m tonnes of coal at any one time. Another unique feature of the project is the large number of different customers for the coal terminal. It is planned that the coal-handling complex in the bay of Sukhodol will make a new export channel available for Russia's small- and medium-sized coal producers.

As part of the design and construction process for the Sukhodol port, Trest Gydromontazh, in cooperation with Morstroytechnology's designers and Sukhodol Seaport LLC's engineers, optimised a whole range of design solutions. In particular, a new construction method was proposed for the foundation sections, with building work commencing not from the shoreline, but from the buttress section in the basin itself, thereby protecting the ongoing foundation works from storm surges. This also meant that the cast concrete of the berths could be installed from the shore, rather than from the water, irrespective of the vagaries of the weather, and at minimal cost in terms of vessel usage. It was also decided to carry out construction work of three sections of the berths in parallel, which given the particular demands of installing pre-cast concrete means that the construction timetable can be adhered to.

Once construction is complete, berth 3 will incorporate wave suppression technology – the berth's foundation will include so-called suppression chambers made up of tetrapods, which will allow the waves to «pass through» the berth’s foundations, thereby reducing the loads on the berth itself.

Sources:

http://portnews.ru/news/282401

http://portnews.ru/news/282400