On 17 September 2019, approval № 27-1-1-3-0136-19 was granted by Russia’s Federal Autonomous Institution “Main Department of State Expertise” (Glavgosexpertisa) for the project documentation and engineering survey findings for the project “Construction of alumina ore terminal at the port of Vanino”.

The project documentation for this terminal was devised and draughted by a team of professional and reliable partners, brought together by the chief design institute, JSC “RUSAL-VAMI”.

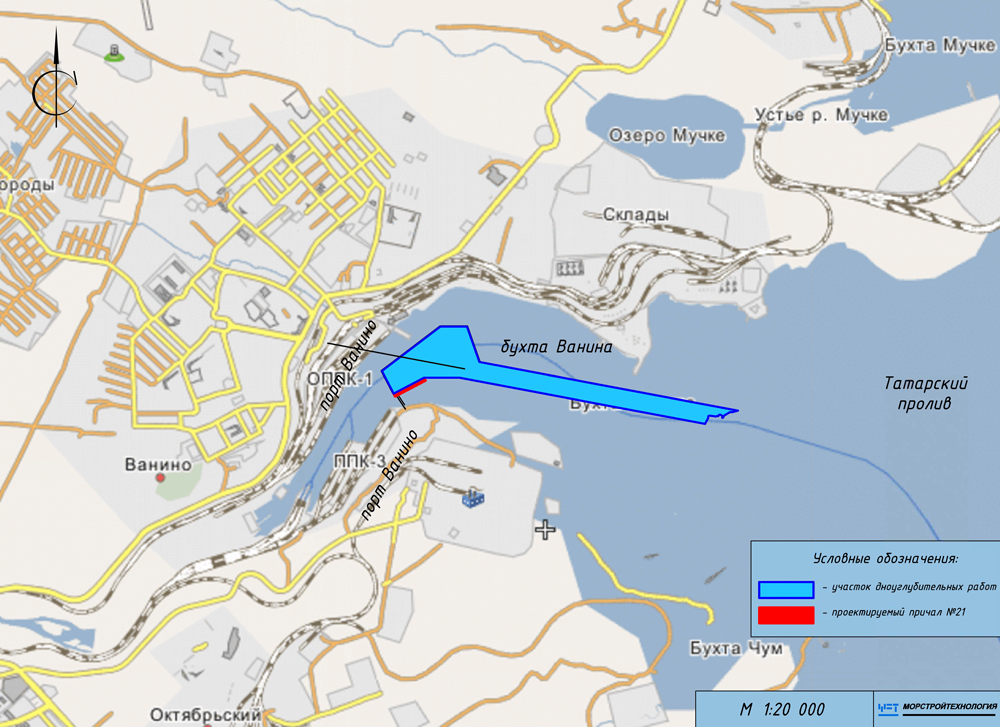

In the approved documentation, the marine element of the terminal was formulated by Morstroytechnology. It is envisaged that the alumina ore will be shipped in on vessels of 60, 000 DWT, for which a new elevated quay with a movable jetty has been designed - quay 21 in the Vanino bay. A unique feature of the project is the requirement from the client-developer to use steel 1020x14mm pipes for the foundation of the quay and jetty, which in turn required the use of a landside supporting row of angled foundation piles of the same diameter. The reinforced concrete foundation of the quay is designed to support two shiploaders with a loading conveyor building and bulk-handling station.

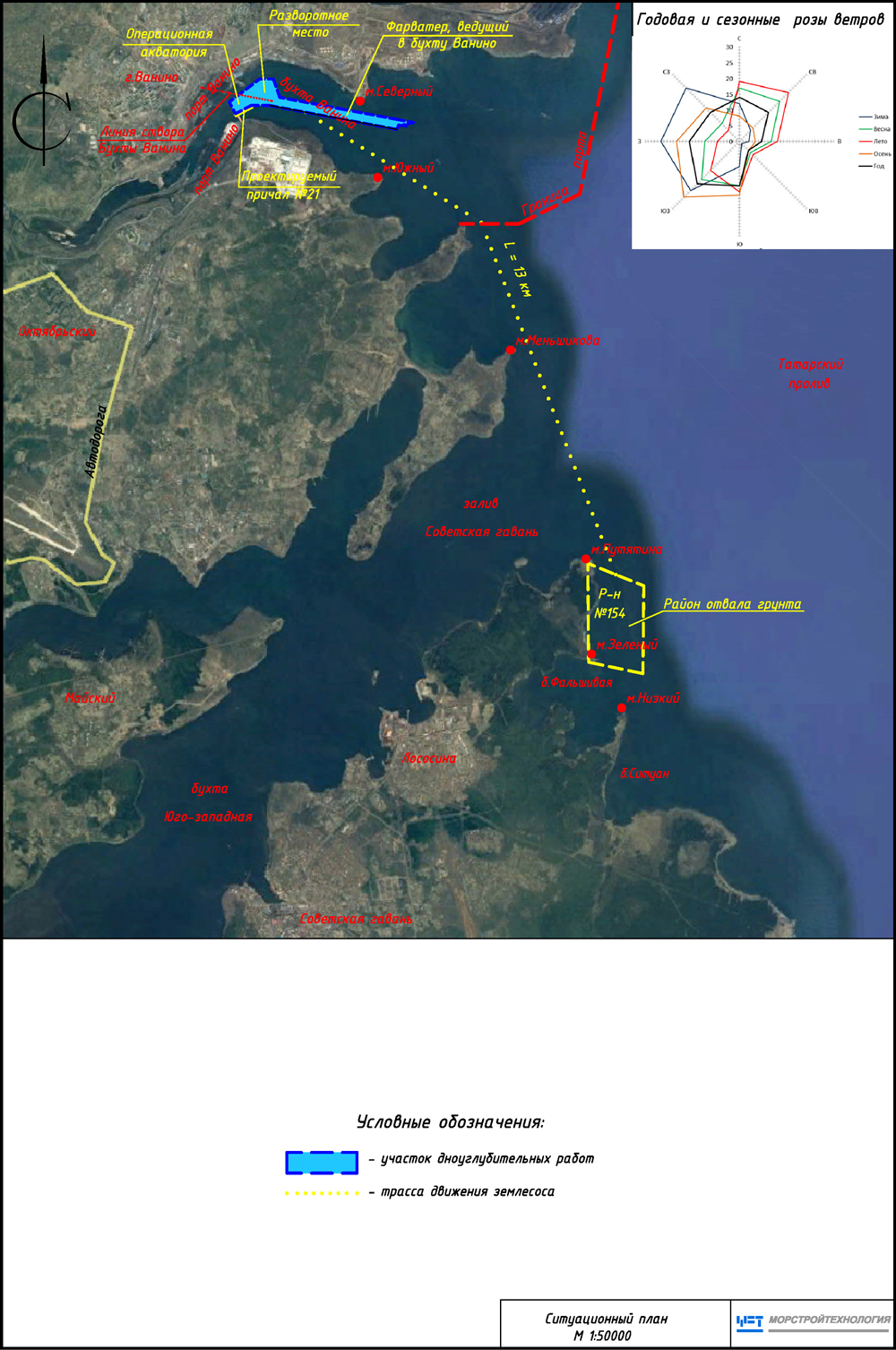

Morstroytechnology also devised the solutions for dredging the port basin and approach channel. When the project is fully developed, the water depth at the quayside, in the port basin and in the approach channel will be 15.3m. During the first stage a volume of 387,000m3 will need to be dredged, during the second stage - 1,562,000m3. The work will be carried out by a self-propelled suction dredger on the sea bed in region 154 (as shown on the sea chart of the Tatar Strait).

Morstroytechnology’s experts drew up sections on navigation equipment and navigation safety, conducted a full range of engineering surveys, and carried out mathematical modelling of wave processes. Cost estimate documentation was also drawn up for the facilities designed by Morstroytechnology.

Documentation has been draughted for both the construction and operation stages.

During the first stage, it is planned to ship in up to 1.5m tonnes of alumina ore on vessels of 35,000 DWT.

In the final stages, the terminal’s capacity should reach 3m tonnes, receiving vessels of up to 60,000 DWT